Nordost Reference Dealers, like us happy folks at Audio Federation, now have another tool that will make sure that the cables their customers receive now sound even more better, yes, more better, than the competition than they already did before. And what a monster, er, make that kick-ass tool it is.

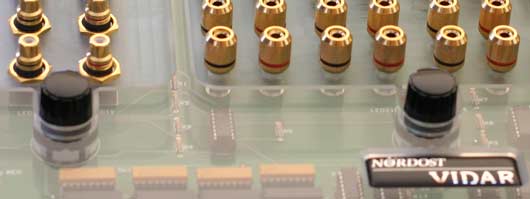

Physically the unit is about 9.5 inches by 17 inches and weighs, I don’t know, say about 10 lbs.

What does it do? And how does it do it?

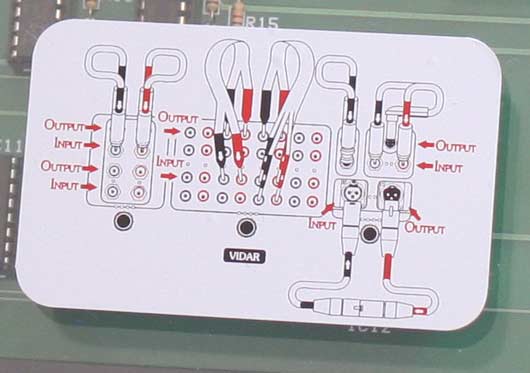

What it does, using 44 amplifiers, is:

1. Neutralizes spurious charges that build up around the cables and its insulation.

2. Conditions the conductor core, which changes the way signals pass through the metal using wide-band sonics

3. Conditions the surface of the conductors using ultrasonics

How does it do it?

The VIDAR “uses a proprietary combination of composite and complex signals to condition the cable.” I bet you could have probably guessed that part.

The process involves ultra-low frequencies (to condition the core of the conductor), ultra-high frequencies (to condition the surface of the conductor), bouncing the signal ping-pong fashionup and down the length of the cable. The manual then goes on to describe how the VIDAR conditions the rest of the conductor as well as the dielectric area above the conductor.

Does it work?

Don’t know yet. It was very cold when it got here so applying power anytime soon was out of the question.

But sometime…. we really should do some listening tests; perhaps one interconnect brand new, and another brand new but burned-in / broken-in / conditioned.

Our general experience has been we have never experienced any deleterious effects from burning in anything, and burning in does seem to add some predictability to the sonics, taking some of the edge off that seems to be occaisionally heard with a brand new cable sometimes… [sometimes we are in too much of a hurry to hear a cable and wham bamm out of the packaging and into the system it goes – so we do sometimes experience what un-burned-in cables sound like 🙂 ].

In any case, it at least looks cool – and it is heavy enough that the cables won’t tip it over. About 95% of the time our customers do want their cables burned-in before we send them out – and we are always happy to do so.