The Edge NL Reference Monoblock Amplifier

Manufacture and Assembly

|

| Each side of the pyramidal NL Reference monoblocks

starts out as a thick piece of aluminum. Here we see one finished

side resting against an unfinished slab of high-grade aluminum. |

|

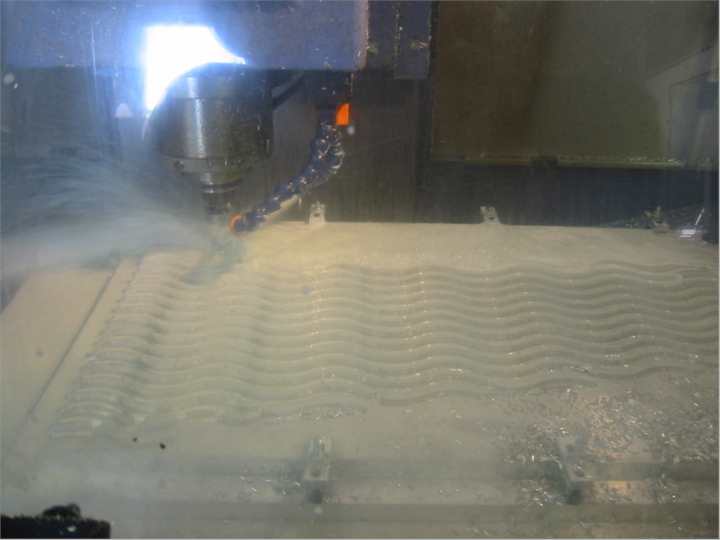

| The milling machine that does the complicated

machining of the aluminum sides. The Leadwell MCV-760AP CNC Vertical

Machining Center is a 3 Axis machine with a 10,000 rpm spindle,

24 position tool changer, and positioning accurate to

+/- .0002 inch

(+/- .0001 inch repeatability) |

|

| A look at one side that is partially completed. Note

the array of tools on the spindle (similar to routing bits) at the top

of the picture. It is only during the final pass that the extraneous

material of the rectangular slab is removed as the slab is cut into

the actual pyramid shape. |

|

| The doors are closed and the milling process has

resumed. It is a noisy process no audiophile should suffer through

for long without ear protection! |

|

| Water is sprayed during milling in order to keep

everything at a reasonable temperature. |

|

| A close-up shot of the action. |

|

| Another close-up shot of the action. |

|

| Yet another refinement pass has completed. |

|

| The coolant (water), still present, is unusually

calm after each stage in the milling process. The impression is one of

'art in transition' from one state to another. |

|

| |

|

| |

|

| |

|

|

Each aspect of the milling process is designed in excruciating

detail.

For example, notice the patterns inside the 'balanced/RCA'

connection area. |

|

| A finished side, ready to be sent to a different

facility for finishing and assembly. There are a number of finishing

options available:

One is powder coating (which leaves a soft, lustrous finish

that is smooth and glorious to the touch and slightly shiny).

Another is a more industrial looking 'anodized finish', similar to

the finish of the amps in the rest of the Edge lineup. |

|

| A partially assembled Edge NL Reference monoblock

amplifier. The cleanliness and care that went into the design is

readily apparent.

Notice the very large transformer assembly (the black box), which

contains vibration dampening and electro-magnetic/radio frequency

shielding technology.

Notice also the large number and size of the capacitors (the black

cylinders).

The NL Reference monoblocks have no air vents, in the traditional

sense. The design, utilizes very thick aluminum, which is not only an

excellent material for shielding against harmful incoming and outgoing

electro-magnetic/radio frequency contamination, but serves as a

massive heatsink as well.

|

|

| A close-up of some of the connections on the

back of one of the amplifiers. Notice the 20-amp IEC standard plug

socket.

Even though the amps do very well with your ordinary house

current, feed them the good stuff (like a dedicated, 30 amp line

straight from the electrical service in your house), and they will

reward you with improved dynamics. |

|

| The amps, now almost completely assembled.

Still missing are the top 'crowns'. The decorative LEDs in the

crown and in the Edge logo on the front can be specified to be in

either red, green, or blue.

These amps were finished using a powder coating and have blue LEDs

(not visible in this picture).

|

|

| The folks at T.H.E. Show not only have a sense of

humor, but they have a good eye as well. |

|